Just How Light Weight Aluminum Spreading Adds To Reliable Manufacturing Solutions

Aluminum spreading plays a necessary role in modern production. Its lightweight nature and corrosion resistance make it a preferred option for numerous sectors. Techniques such as die spreading and sand casting permit the development of intricate get rid of very little waste. The combination of automation further enhances production efficiency. Nevertheless, the ramifications of these developments prolong beyond simple efficiency. Comprehending the broader influence exposes substantial understandings into the future of manufacturing

The Advantages of Aluminum in Production

Different steels are made use of in production, light weight aluminum stands out due to its distinct buildings that enhance production effectiveness and item efficiency. Its light-weight nature notably reduces transport expenses and power demands in various applications. Aluminum's exceptional deterioration resistance assurances durability and toughness, minimizing the demand for regular substitutes and upkeep. This steel can be quickly built and formed, permitting functional layout choices that fulfill details market demands. In addition, light weight aluminum displays remarkable thermal and electrical conductivity, making it an excellent selection for applications requiring efficient warm dissipation and electrical monitoring. The recyclability of aluminum also plays a vital function in sustainable production methods, as it can be recycled without shedding its intrinsic residential or commercial properties. Generally, the advantages of aluminum in producing bring about cost savings, enhanced product longevity, and a reduced ecological footprint, making it a preferred material in countless sectors.

Key Aluminum Casting Techniques

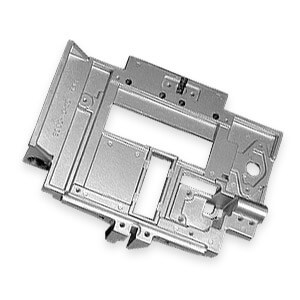

Light weight aluminum spreading strategies are vital for generating top quality components in different producing processes. The main approaches consist of sand spreading, die spreading, and investment spreading. Sand casting includes producing a mold and mildew from sand, which permits complex shapes and big components. This technique is usually preferred for its cost-effectiveness and flexibility. Pass away casting, on the other hand, makes use of high-pressure to infuse molten light weight aluminum into steel mold and mildews, causing exact, consistent parts suitable for high-volume production. Financial investment spreading supplies remarkable surface area finish and intricate information by using a wax pattern that is melted away to create the mold and mildew. Each of these strategies has specific applications and benefits, enabling producers to choose the most suitable method based upon factors like production complexity, material, and volume specs. By understanding these key methods, makers can boost their manufacturing efficiency and ensure the honesty of their aluminum components.

Effect On Automotive Sector

As the automobile industry progressively prioritizes lightweight materials to boost gas efficiency and performance, aluminum spreading has actually become a crucial option. This production process permits car manufacturers to produce complicated elements with reduced weight without jeopardizing architectural honesty. By using light weight aluminum casting, suppliers can develop components such as engine blocks, transmission real estates, and suspension elements that are not only lighter however additionally display excellent thermal conductivity and rust resistance.

Moreover, the flexibility of aluminum spreading strategies allows the production of complex designs, facilitating development in car visual appeals and performance. As lorries end up being a lot more technically progressed, the capability to incorporate attributes like advanced safety systems and electric drivetrains ends up being important.

Aerospace Applications of Aluminum Casting

Light weight aluminum casting plays a critical role in aerospace applications by making it possible for the production of lightweight structural parts that enhance fuel performance. Furthermore, the precision of aluminum spreading permits for the development of intricate engine parts, which are important for peak performance and reliability. This combination of lightweight products and accurate engineering placements light weight aluminum spreading as an essential innovation in the aerospace industry.

Light-weight Structural Components

In the pursuit for enhanced performance and efficiency in aerospace applications, lightweight structural elements have actually become increasingly crucial. Aluminum spreading plays a crucial role in this endeavor, offering producers with the capacity to generate parts that are both strong and light-weight. The low density of light weight aluminum allows for considerable weight decreases without jeopardizing architectural integrity, which is critical for aircraft performance and gas effectiveness. In enhancement, aluminum castings can be engineered to meet certain layout needs, allowing the development of complicated geometries that conventional production methods may battle to achieve. This convenience not just improves production procedures however also contributes to general expense financial savings. As the aerospace industry remains to emphasize sustainability, the need for lightweight light weight aluminum parts is anticipated to rise, better advancing technology in production.

Accuracy Engine Parts

Producers progressively count on light weight aluminum casting to produce precision engine components for aerospace applications, driven by the material's special homes. Light weight aluminum's light-weight nature significantly lowers general airplane weight, enhancing fuel performance and efficiency. Its outstanding deterioration resistance warranties longevity in harsh environments, making it perfect for vital engine elements. In addition, light weight aluminum spreading allows for limited resistances and complex layouts, crucial for optimizing engine efficiency and reliability. The casting procedure likewise sustains mass production, allowing makers to fulfill high demand while preserving top quality requirements. As aerospace modern technology continues to advance, the duty of aluminum spreading in creating accuracy engine parts will certainly be essential in attaining greater efficiency and advancement in aircraft layout and performance.

Sustainability and Environmental Benefits

The growing emphasis on sustainability in production has positioned aluminum spreading as a leading service for ecologically aware manufacturing. This process utilizes recycled light weight aluminum, which significantly lowers energy usage compared to primary light weight aluminum manufacturing. By leveraging scrap metal, producers can reduce their carbon footprint and reduce waste, straightening with worldwide sustainability objectives.

In addition, aluminum casting produces fewer damaging discharges, adding to a cleaner setting. The lightweight nature of light weight aluminum likewise improves gas efficiency in transportation applications, better advertising environment-friendly practices.

Furthermore, the longevity and rust resistance of aluminum result in longer item life expectancies, reducing the demand for constant replacements and preserving sources. As industries increasingly focus on lasting options, aluminum casting stands apart as an ingenious technique that not only meets manufacturing needs yet also sustains ecological stewardship. This dedication to sustainability settings aluminum spreading as a crucial gamer in the change in the direction of a greener manufacturing landscape.

Cost Effectiveness in Manufacturing

Cost efficiency is a considerable benefit of light weight aluminum spreading, enhancing its sustainability benefits - aluminum casting. The procedure of aluminum casting permits the manufacturing of complicated forms with minimal waste, which is specifically essential in a competitive production environment. Making use of aluminum reduces power expenses, as it has a lower melting factor contrasted to various other metals, bring about minimized energy intake throughout manufacturing

Furthermore, aluminum's light-weight residential or commercial properties add to lower delivery and managing expenses, further improving general cost performance. The toughness and rust resistance of aluminum cast products additionally mean that they require much less upkeep and replacement with time, resulting in lasting financial savings for suppliers.

Advancements in casting innovations, such as boosted mold and mildew layouts and automation, have streamlined production processes, lowering labor expenses and raising result effectiveness. Overall, expense performance in light weight aluminum casting plays an essential function in optimizing manufacturing procedures and sustaining affordable rates strategies.

Future Patterns in Light Weight Aluminum Casting

The future of light weight aluminum spreading is significantly formed by innovations in automation and sustainable product developments. Automation innovations are anticipated to enhance performance and precision in the casting procedure, while sustainable techniques aim to reduce ecological impact. With each other, these fads guarantee to redefine manufacturing criteria and methods within the light weight aluminum spreading industry.

Automation in Light Weight Aluminum Casting

Accepting automation is changing light weight aluminum casting procedures, leading the method for improved efficiency and accuracy. Automated systems streamline production by decreasing human treatment, decreasing mistakes, and increasing throughput. Technologies such as robot arms and computer numerical control (CNC) equipments enable accurate and constant shaping of aluminum parts. In addition, wise sensing units keep track of various criteria in real time, ensuring perfect problems throughout the spreading process. This integration of automation not just shortens preparations but also improves item quality by keeping tighter resistances. As makers significantly embrace these sophisticated modern technologies, the aluminum spreading market is readied to experience considerable enhancements in operational effectiveness, cost-effectiveness, and competitiveness in the international market.

Sustainable Material Innovations

Regularly Asked Concerns

What Sorts Of Light Weight Aluminum Alloys Are Generally Made Use Of in Casting?

Commonly used aluminum alloys in casting consist of 356, 380, and 413. These alloys are preferred for their exceptional fluidness, toughness, and rust resistance, making them suitable for a selection of industrial applications.

How Does Light Weight Aluminum Spreading Contrast to Other Steel Casting Approaches?

Aluminum casting generally provides reduced weight, premium corrosion resistance, and far better thermal conductivity compared to other metal spreading methods. Furthermore, it permits elaborate layouts and faster manufacturing cycles, improving overall manufacturing performance and performance.

What Industries Advantage Many From Aluminum Spreading?

The vehicle, aerospace, and electronics markets profit most from aluminum casting. These industries utilize its light-weight, corrosion-resistant buildings to boost efficiency, minimize gas usage, and boost general item efficiency, making light weight aluminum spreading increasingly vital.

Exist Particular Style Limitations With Aluminum Casting?

Yes, aluminum spreading has design read more constraints, consisting of limitations on wall thickness, facility geometry obstacles, and prospective issues with attaining limited tolerances (aluminum casting). These factors can affect the overall strength and performance of the end product

How Is Quality Assurance Maintained in Aluminum Spreading Processes?

Quality assurance in aluminum casting procedures is preserved via strenuous inspections, adherence to standardized procedures, and the use of advanced modern technologies. Regular monitoring guarantees dimensional precision, surface area honesty, and material uniformity throughout manufacturing, advertising overall dependability.

As the vehicle industry increasingly prioritizes lightweight materials to boost fuel performance and efficiency, aluminum spreading has actually arised as a critical option. Aluminum casting plays a vital function in aerospace applications by making it possible for the manufacturing of light-weight structural parts that boost fuel performance. Price effectiveness is a significant advantage of aluminum spreading, matching its sustainability benefits. Embracing automation is transforming light weight aluminum spreading processes, leading the way for enhanced effectiveness and accuracy. Recycled light weight aluminum use has gained grip, considerably reducing energy consumption contrasted to main light weight aluminum production.